Seiko Epson Corporation recently exhibited its Direct-to-Shape Printing System, an inkjet printing solution for printing directly on 3D objects, at Automatica, in Messe München, Germany. The trade fair for smart automation and robotics, Automatica ran June 24-27. This marks the first overseas exhibition of the solution. With this event as a launchpad, Epson will begin full-scale global commercialization.

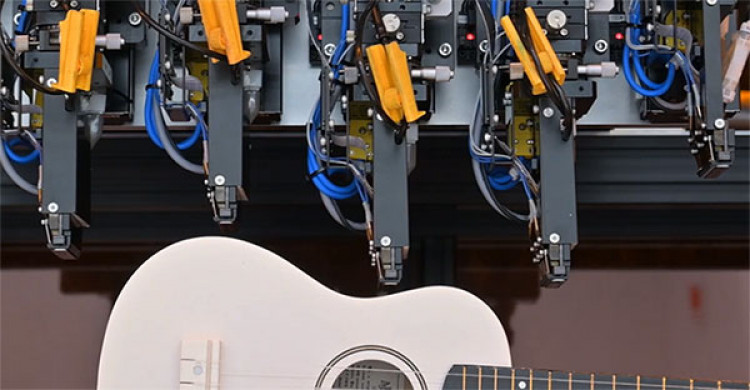

The system combines Epson's S800 PrecisionCore printheads with an Epson industrial robot. The S800 is the smallest printhead in the PrecisionCore series. This small size allows printing on complex shapes such as grooves and curves. A 6-axis robot and lifting mechanisms that independently raise and lower the printheads are used in combination to allow the Direct-to-Shape Printing System to flexibly accommodate printing on objects from different angles with outstanding quality and accuracy.

It digitalizes traditional analog printing, streamlining manufacturing processes by automating manual tasks and using space efficiently. Epson's inkjet technology deposits ink only where and in the volume needed. This reduces the amount of material used and wasted, making inkjet printing more environmentally sustainable. Inkjet systems also eliminate the need for plates or special materials for each operation, enabling cost-effective personalization and customization.

It's expected to be used in fields where there is a demand for printing on 3D shapes, such as helmets for athletics and industrial use, automotive parts (interior and exterior), home appliances, sporting equipment, apparel, accessories, and more. In addition to graphics applications, Epson envisions the Direct-to-Shape Printing System being used in functional printing, such as the printing of sensors with conductive ink and the coating of 3D objects.

Key Features of Direct-to-Shape Printing System

- Precise and accurate printing on 3D objects

- 600 dpi x 600 dpi resolution with S800 PrecisionCore printheads

- Flexible printing angles via a 6-axis robot and independent lifting mechanisms

- Precision trajectory control and image processing for curved surfaces

- Supports up to 5 ink colors (e.g., C/M/Y/K/White), customizable

Business Model and Partnerships

Epson has been conducting ongoing R&D at Inkjet Innovation Lab Fujimi in Nagano Prefecture. The company is actively pursuing global partnerships for commercial deployment. The company offers the hardware and total solutions, including ink, image processing, and after-sales support. Epson also supports ink selection and operational assistance in collaboration with optimal partners.

The preceding press release was provided by a company unaffiliated with Promo Impressions. The views expressed within may not directly reflect the thoughts or opinions of the staff of Promo Impressions.

New Study Finds Convergence Across Print Segments is Delivering Revenue and Profits

New Study Finds Convergence Across Print Segments is Delivering Revenue and Profits

AutoTran Introduces Jigless UV-LED Printing

AutoTran Introduces Jigless UV-LED Printing

The Shifting Regulatory Landscape for 2026

The Shifting Regulatory Landscape for 2026

Why Mission Matters

Why Mission Matters

Case Study: Building an AI-Powered Future

Case Study: Building an AI-Powered Future

LogoJET Introduces TruFlat as Certified Blank Media for UV Printing

LogoJET Introduces TruFlat as Certified Blank Media for UV Printing